- Over 25 years of experience in preserving and enhancing the beauty of patina of 200 year old floor boards.

- Total mastery of the antiquing knowhow gained in the past 30 years.

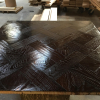

- Complex multi-step elaborate finishing processes enhancing real beauty of wood.

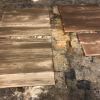

First, Last & Always has worked on about 20 projects in the last 25 years where 250-150 year old floor boards were purchased in Europe and the goal was to install floor that would function well in our environments but that would feel and look as antique and authentic as the old floor would in a Manor house in France or in England. Rather then hiring a lawyer to write up an extensive disclaimer I have purchased a wood kiln and we start by kiln drying this old and air-dried only lumber. Not only are we by now true masters of leaving such replicas behind, but we have developed a lot of unique new approaches and are making these old floor boards look more beautiful than anyone has ever seen.

Texturing the surface of wood started as a hobby for me back in 1994. I had some beautiful wide plank Walnut boards left over from a sanded smooth floor project. I remember being intrigued by the experimentation of using all sorts of metal tools. To me wood became so much more interesting when it had some, any texture, rather than just a smooth surface. However, I have noticed at the same time that finishing of textured surfaces was an art form in itself. It was so easy to oversaturate with pigments the rougher, more open surface of wood. All of a sudden I knew that these textured projects were more compelling to me, and every weekend I ended up spending hours developing new ideas, making samples. In 1996 we started working in Pebble Beach for John Matthams of International Design Group among others. I felt like a kid in Disneyland, as the entire vibe of that place coincided with exactly the same antique look I was spending so much time on. Since then we have completed over 25 projects on 17 Mile Drive alone. In Pebble Beach we have gained a lot of experience in antiquing wood surfaces to resemble the wood of original old surfaces we were often given on projects as a sample to match.

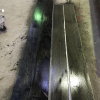

The majority of hardwood floors installed by us between 1990 and 2007 have had the surface either sanded in place or the distressed texture of boards we had done in the workshop was tuned up after installation and floors ended up being finished in place. And then a gradual change started taking over our industry. The chemically treated surface of wood we often achieve these days by the application of various metal derivatives, oxidizers and other natural substances, affect wood grain differently than the pigments of the old fashioned wood stains used to. Wood ends up looking more natural and less painted, and more attractive. Sometimes we are able to perform such multi step finishing techniques in place but very often the processes are too wet and too difficult to apply on installed floors. Besides, we seem to be installing more and more of the very wide plank floors these days; 12”, 14” or even 17” widths of planks. These planks are simply too wide to be installed without micro bevels, and then we might as well install them with a very interesting coloring that could not be achieved in place.Therefore more and more often we pre-treat and seal boards one by one at our workshop, and install pre-colored and sealed boards and only do final finishing of a floor in place.

A friend of mine, an industry partner was traveling in the mountain states recently, talking to architects and contractors. He mentioned to me that he was told one of my samples was being matched in Holland for one of the projects. He was surprised to find me laughing. But it happens all the time and I consider it a compliment. Whereas 10 years ago I might have been looking at various samples of chemically treated surfaces, wondering how this could have been done, these days I am the one who often develops new techniques and color tones that are then being sent to the best vendors in Europe, or to some other finishers, so they could match it and apply on lower end platform. For the last decade I had been totally consumed by my experimentation and gaining skills letting me, by way of chemical treatment processes, bridge the spectrum of the color tones I could visualize and deemed attractive. I had been neglecting the business side of my operations by being a chemist first and foremost. But now, although I still experiment, i feel like I can get anywhere with the coloring techniques I have devised. Not to say that there never is a wrong turn, and a finishing method I would not repeat. But I have developed so many useful approaches, that now I can focus in other areas of my business. Like, so much overdue, this mobile website.