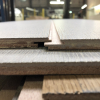

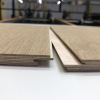

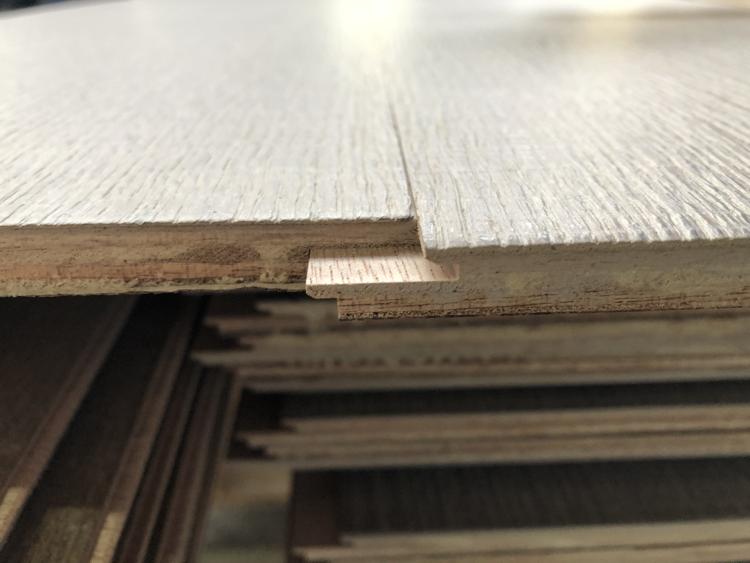

- Wood vacuum dried to below 4% of moisture.

- Subjugation of wood cell’s memory of movement.

- Power washing of boards prior to finishing allowing heavy duty washings as part of ongoing maintenance.

Lumber mills in America kiln dry lumber to 7% - 8% of moisture. In France most of wood gets kiln dried to 9% - 10% of moisture. Torben Hansen vacuum dries Oak veneers to 4% of moisture and keeps them under pressure until wood cells lose their memory and no longer move the same way as other lumber does. During this drying process the surface of wood veneers moves under pressure giving us this incredible shrunk effect. It feels natural as created by nature and not by tools. It adds texture and beauty and ends up looking completely unique. You can feel it under your feet and you get the sense that you are walking on a therapeutic surface.

The first Schotten & Hansen project we have done in San Francisco was an Oyster floor installed in a house on Broadway back in 2012. In the basement these 9”-14” wide planks were glued to cork glued only to a concrete slab. There were no metal fasteners holding down our floorboards. Due to some accident the basement had flooded and the floor was submerged under a few inches of water for hours. A couple of days later after the water and the majority of moisture had been removed we were standing there with the architect and a builder looking at the floor that seemed not to show any signs of damage at all. That was when I realized that Schotten & Hansen floors were the most stable hardwood floors in existence.

I have seen many inspiring photographs of wide and long plank floors in other companies’ great marketing products. Looking closer at these photos I can see gaps between boards. These gaps look real and natural, and well suited to the interior. However, most of my clients do not want to see any seasonal gapping between their boards. They want their interiors to stay intact at all times without any workers having to come and fill gaps on hot summer or cold winter days, or me repeating the same old tale about wood being a living surface reacting to sudden changes in environment. With planks as wide as 17”, our next Schotten & Hansen installation, installed over radiant heating, I have no concerns of ever experiencing any problems due to movement of boards. Solid Oak planks could only be installed lose, with gaps, to be safe in such condition, but many of the engineered floors at these dimensions would also experience seasonal and pretty much constant problems. Schotten & Hansen technology lets us all rest assured.