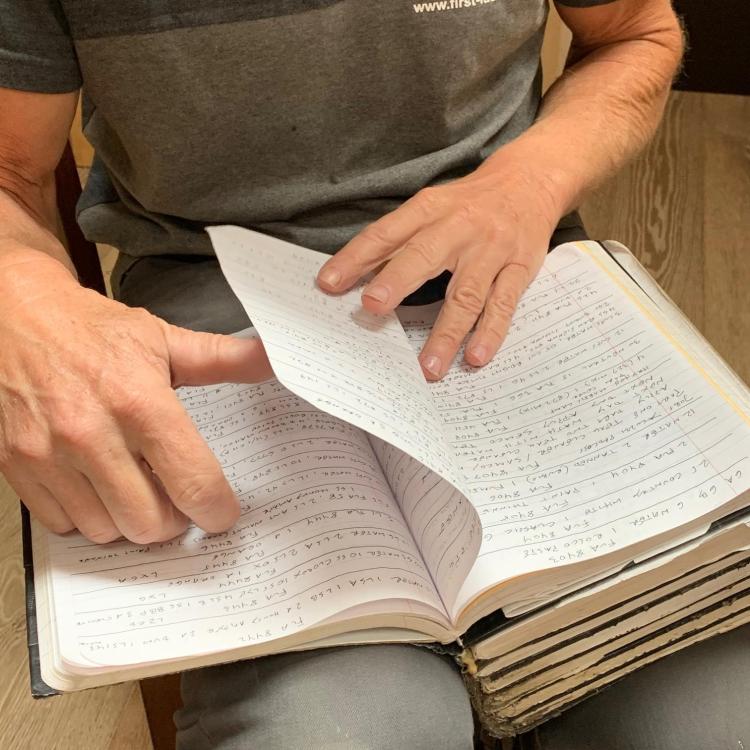

- Constant experimentation and re-evaluation of what one has learned nurtures one’s expertise.

- Stability of color tones often depends on the process a given color tone was achieved.

- You can have two color matching samples of a completely different color stability.

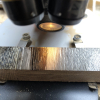

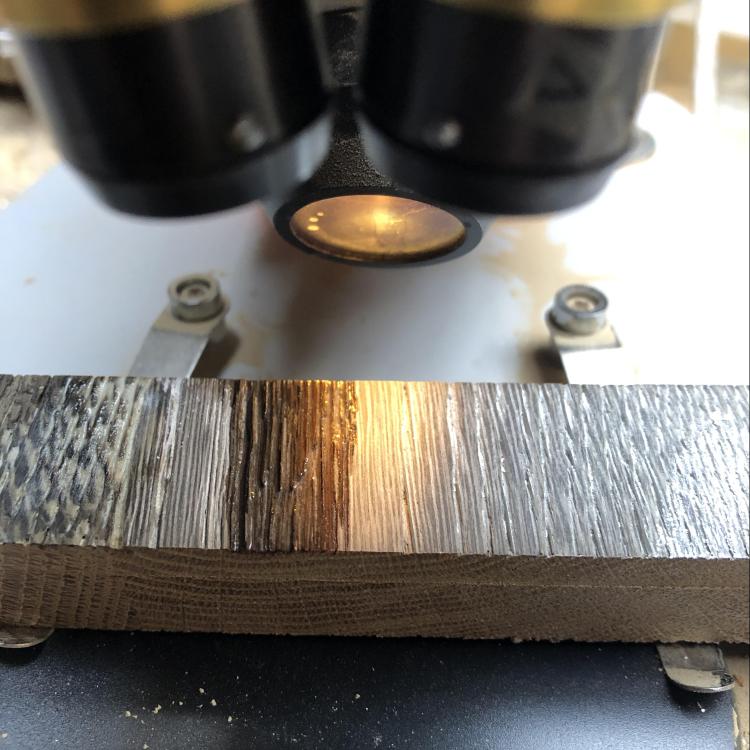

What makes my work most interesting to me is the constant development of new ideas of wood treatment. It is interesting that some of the most basic natural substances used by humans in other ways for centuries, affect wood in the most peculiar ways, reacting with the tannin content of wood. There is such a multitude of potential ingredients and a limitless range of various formulas, strengths, and ratios, as well as the sequence of applications, that I could probably spend the rest of my life full time doing nothing but developing new color treatments of wood. As is the case with all other forms of experimentation, the overwhelming majority of results fail and are not consequential. But every now and then something beautiful just appears opening new doorways of possibilities. And this exact treasure is truly worth the search. Part of my research and development work goes into testing the stability of color tones. I have noticed that often the more complex the finishing process with a multitude of steps involved, the more stable the color tone becomes. If we installed an oak floor, sanded it, and left it unfinished, you would see how much it would change the color near windows, as compared with areas not exposed to daylight. Very often the simple methods of coloring wood with dyes or pigments accentuate this problem of a color change. Light woods of a very hard cell structure like Hickory Pecan, stained to a dark color will fade tremendously in sun heat exposed areas. But a lot of the chemical processes of colors with the gray undertone are very color stable. That is another reason we use these processes lately. I spend a lot of time recently matching my own samples with different approaches and processes, so I can achieve more color stability, and so I am able to use any topcoat product I chose to use. This can get us a beautiful chemically achieved coloring and a bulletproof finish that does not require any maintenance.

My inspiration partially comes from observing the results of my constant tests. Last time I viewed any video transmission for even a few minutes was when president Obama was getting elected for the first time. It might seem insane to anyone that I would prefer to watch wood grain getting affected by a metal derivative solution, rather than watching some great movie. But this exactly is one of my forms of relaxation. Most of my creative work happens on weekends when I am alone with music. Wood does not talk to me so I can concentrate and a deeper channel of communication exists. I really like coming up with some new color tone on Oak or Walnut, that appeal to me. And it seems that not only to me. My samples are often shipped to various places where they are being matched by simplified methods. The problem with this approach is that although the color tone might end up looking close, the floor will often look boring because I develop complex multi-step processes for a reason. Just like reading a few pages synopsis summarizing some great novel will not leave you with quite the same experience and outcome as reading the book, so the wood coloring similar to a result of one of my multi-step processes achieved in a simplified way will not present the highlights and tone hues of the original. A little sample may look close enough, but the entire surface will often turn boring and disappointing